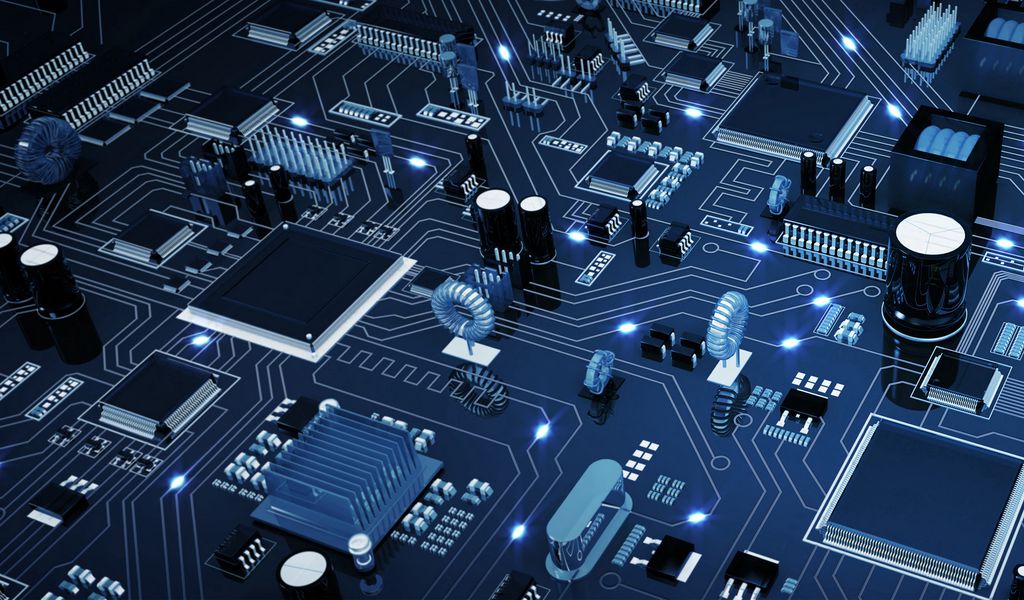

PCBs have revolutionized the electronics industry by making electronic devices smaller and more powerful. They are made up of a number of interconnected boards with a variety of components, such as transistors, resistors, capacitors, and diodes. PCBs come in many shapes and sizes, but all share some common features.

What is a Printed Circuit Board (PCB)?

A Printed Circuit Board, also known as a PCB, is a piece of hardware that allows electronic components to be interconnected. PCBs are typically made from fiberglass and copper, and they are used extensively in electronics. One of the primary functions of a PCB is to provide a platform for mounting electronic components. Additionally, PCBs help to route electrical signals between those components.

By providing a uniform platform and routing capabilities, PCBs help to ensure that electronic devices function properly. PCBs come in a variety of shapes and sizes, and they can be used in a wide range of applications. Some common applications include consumer electronics, medical devices, and automotive systems. PCBs are also relatively inexpensive when compared to other types of electronic hardware. This makes them an attractive option by APCT for many manufacturers.

Different Types of PCB

1. Single Layer PCB

A single layer PCB is a printed circuit board (PCB) with only one layer of copper foil. Single-layer PCBs are the simplest and cheapest type of PCB, and they are typically used in low-power or hobbyist applications.

Although single-layer PCBs have some disadvantages, single-layer PCBs remain popular because they are inexpensive and easy to fabricate. They are ideal for low-power or hobbyist applications where reliability is not a major concern.

2. Double Layer PCB

Double layer PCBs, also known as multilayer PCBs, have two layers of conductive material. This arrangement allows for more efficient use of space on the board and can create a more reliable circuit. Additionally, double-layer PCBs are able to handle more current than single-layer boards.

3. Multi-Layer PCB

Multi-layer PCBs are boards with more than one layer of circuitry. The multiple layers can be used to create different circuits or to stack components on top of each other. Multi-layer PCBs offer several advantages over single-layer boards. They are more reliable and less likely to fail, and they can handle more power and data. They are also easier to manufacture since the different layers can be created separately and then assembled.

4. High-Density Interconnect (HDI) PCB

HDI PCBs are a specialized type of printed circuit board used in electronic devices. They are characterized by their high density, which allows for more components to be crammed onto a single board. This makes them ideal for use in small devices like cell phones and tablets.

HDI PCBs are made by using a variety of techniques to create smaller traces and pads than are typically found on standard PCBs. This allows more components to be placed in a given area, resulting in a higher density board. HDI PCBs have become increasingly popular in recent years as the demand for smaller and more powerful electronic devices has increased.

5. High-Frequency PCB

A high-frequency PCB must be designed and manufactured with special considerations in mind. The traces on a high-frequency PCB must be much narrower than those on a regular PCB, and the spacing between them must be much greater. This is because high-frequency signals can travel along very thin traces, and any interference between traces can cause signal degradation. The layout of a high-frequency PCB is also critical. The components on a high-frequency PCB must be placed in such a way that they do not interfere with each other.

What is the PCB Manufacturing Process?

The PCB manufacturing process begins with the preparation of the substrate material. The substrate is typically a fiberglass sheet that has been coated with a thin layer of copper. The copper layer is used to create the circuit traces that will be used to connect the electronic components. The next step in the process is to create the masking pattern. The masking pattern is used to protect certain areas of the copper layer from being etched away. The masking pattern is created using a photomask, which is a piece of glass that has been coated with a thin layer of aluminum.

What is the Importance of PCBs?

Without PCBs, electronic devices would not be able to function. They are used in almost every type of electronics, from cell phones to televisions. PCBs are important because they allow devices to communicate with each other and perform the tasks they are designed to do. They also help protect electronic components from damage, which can cause malfunctions or even fires. Without PCBs, our lives would be very different and much more difficult.

Conclusion

In conclusion, a PCB is an important component of electronic devices. It helps to connect and support the different parts of the device. There are many different types of PCBs, so it is important to know the specific needs of your project. When choosing a PCB, you should consider the number of layers, the size, and the type of material. You also need to decide on the manufacturing process. With so many options available, it can be difficult to choose the right PCB for your project.